The PyreJet™ is a single, wall-mounted, multi-function tool for Electric Arc Furnace (EAF). It is a patented innovative solution for maximizing EAF energy efficiency and steel output.

An EAF multi tool designed to combine the functions of an oxy fuel burner and oxygen lance and enhance foamy slag from carbon injection

- Designed for solid charge mixes

- Decreases electrical consumption

- Lowers power on time

- Reduces electrode consumption

- Improves refractory life

- $1 to $3 savings per ton obtained

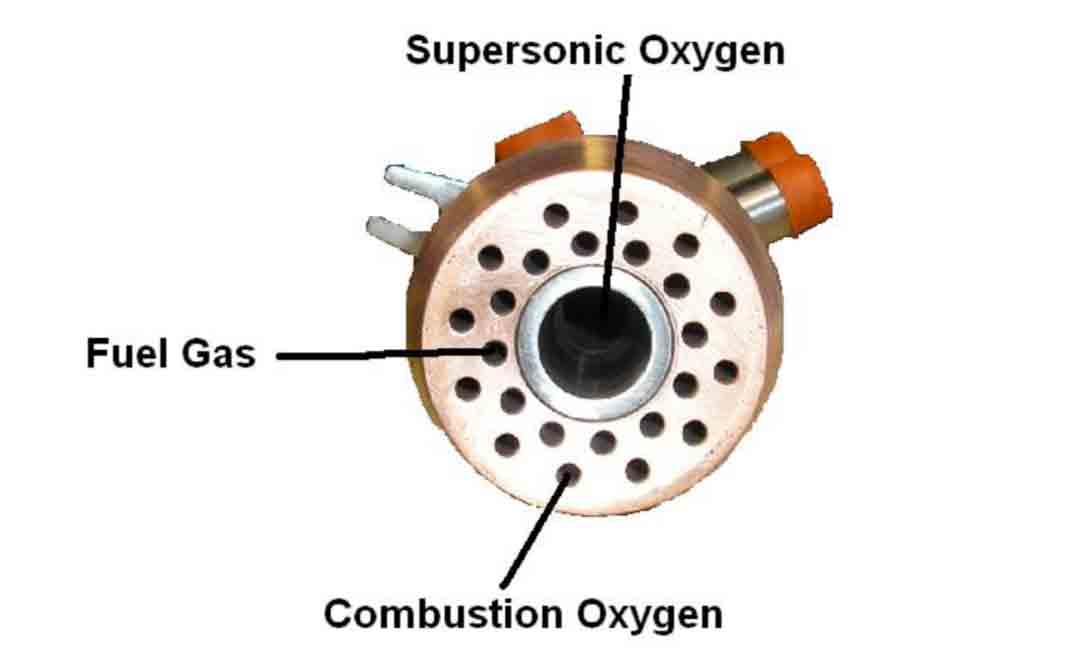

PyreJet™ combines long range compact flame shrouded supersonic oxygen jet and focused carbon fines injection in one simple, low maintenance unit. PyreJet's™ unique design allows for a wide range of firing capacity and carbon/oxygen injection rates to accommodate any furnace size, grade mix, and heat cycle.

PyreJet™ offers significant operating and maintenance advantages over other decarburizing and chemical energy devices for EAF steelmaking.

- 60 kWh/ton Reduction

- 12% Reduction in Power On Time

- 1% Increase in Metallic Yield

- 20% Reduction in Electrode Consumption

- More than 30% Reduction in Refractory Consumption

- Improved productivity 30%

- Reduced operating cost

- No moveable parts

- Multipoint focused carbon/oxygen co-Injection

- Balanced melting pattern

- Improved slag foaming

- Low maintenance

- High reliability

- Minimal installation cost

- Efficient carbon monoxide post combustion