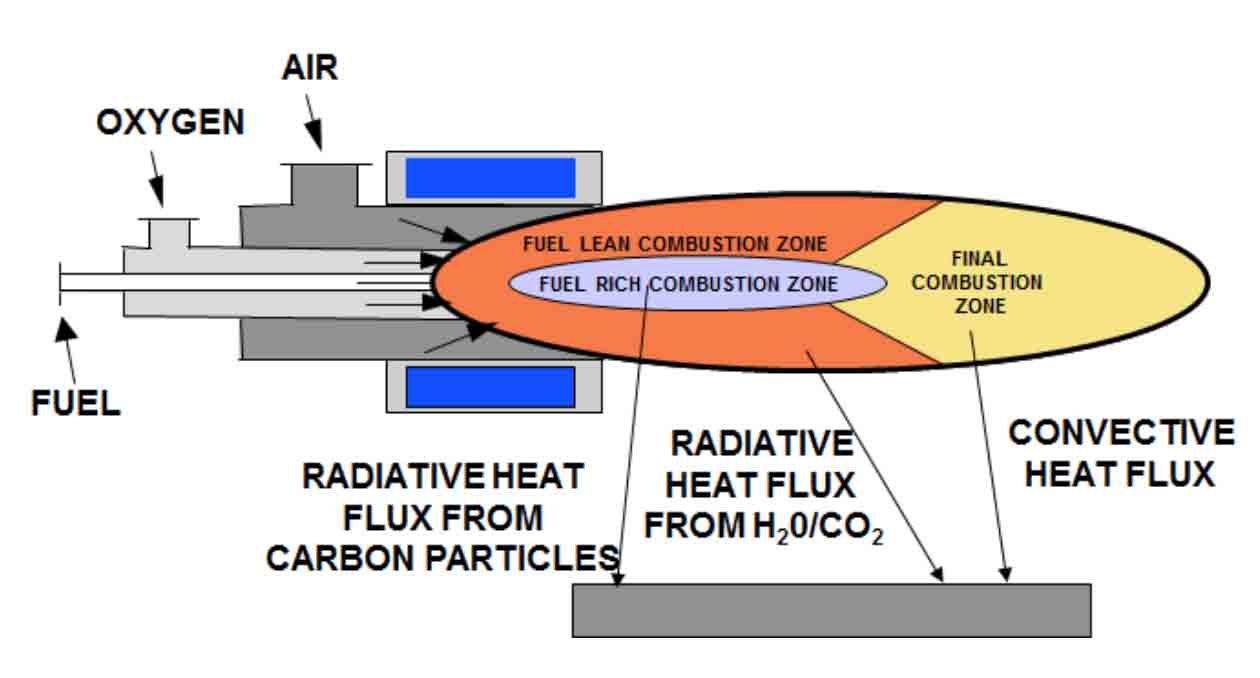

The PyreTron™ patented burner uses independently controlled streams of gas, air and oxygen to overcome the conventional limitations of oxygen use. It produces a flame with high temperature, luminosity and velocity, increasing both radiative and convective heat transfer.

This is accomplished by using an oxygen staged combustion approach which accelerates fuel pyrolysis inside an extremely hot flame core, contained in a specially structured flame envelope.

In the first combustion stage, the fuel is mixed with a sub-stoichiometric amount of pure oxygen inside the central portion of the flame, creating a fuel rich flame core, in which the fuel is partially combusted and pyrolyzed.

This pyrolysis of fuel in the flame core creates a cloud of micro particles of carbon and hydrocarbon radicals of extremely high emissivity and temperature, due to the complete elimination of nitrogen inside the flame core. The second oxidizer, usually air or oxygen-enriched air, is introduced in the second combustion stage, the fuel lean zone, to complete the combustion reaction in the final combustion zone.

Benefits

By combining oxy-fuel and air flame, flue gas heat losses are reduced while available heat and productivity are increased:

- No increase in total energy costs

- Reduced fuel consumption

- Optimized oxygen usage (oxygen is only part of the total oxidant.

- Lower exhaust gas volume, which lowers temperature, which could lead to lower temperature rating of bags for the baghouse

- Reduced CO and other combustibles in exhaust (lead)

- Unaffected metallic yield / improved yield in brass/copper furnaces +0.5 to 1%

- Improved refractory life (copper/brass and aluminum)

- Increased turn-down

- Improved control of melting/refining processes (temperature, oxygen flow ...)

- Flame patterns optimized to process needs

- High flame velocity during whole range of firing rates

Flame Characteristics

- Increased radiative heat transfer efficiency from the highly luminous, high-temperature flame core

- Maximum convective heat transfer from high velocity flame

- Maximum combined radiative and convective heat transfer based on process temperature

- Low NOx formation

- Optimized for the use of different fuels

- Improved productivity 30%

- Minimum excess total oxygen required for complete combustion of fuel

- Greater than 10/1 turn down