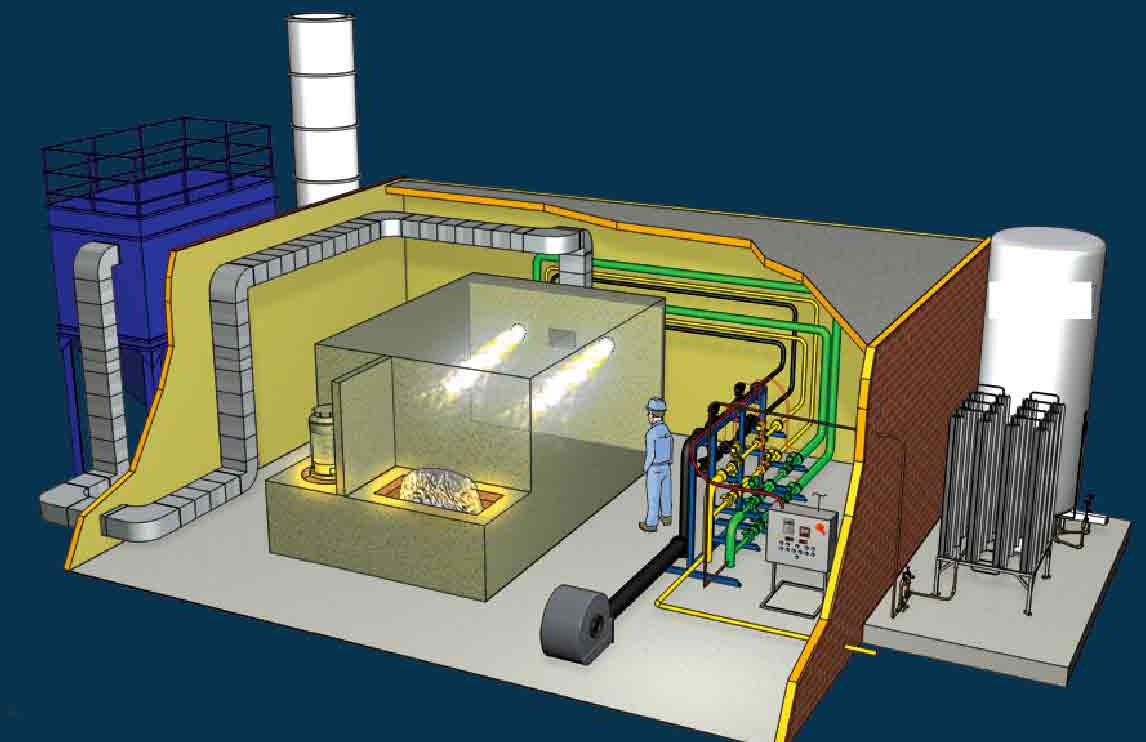

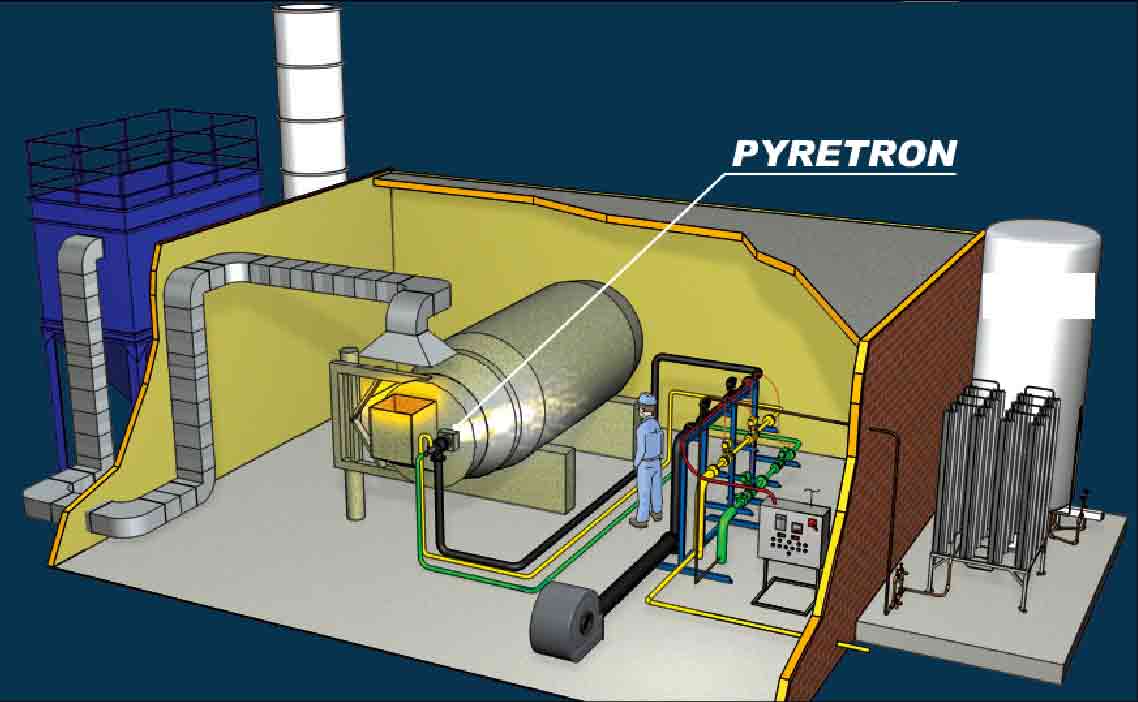

ACIs patented PyreTron ™ and PyrOx™ burner systems are designed and modeled to optimize the

furnace performance and guarantee improvement in the operating process. Our burner technologies

use independently controlled streams of gas, air and oxygen to overcome the conventional limitations of

oxygen use. They produce a flame with high temperature, luminosity and velocity, increasing both

radiative and convective heat transfer.

Key characteristics of the ACI burner systems for use in copper and brass furnaces are following:

Melting furnaces:

- Increased melt rates (50+%)

- Allows use of cheaper, lower grade raw materials

- Metallic yield unaffected (brass)

- Reduced total energy cost

- Improved refractory life

- Improved refining performance

Anode/holding furnaces:

- Reduced total energy costs

- Faster molten metal superheating capability to:

- improve caster performance

- improve castings quality

The PyreTron™ and PyrOx™ burners has been successfully used in over 200 installations in the steel,

copper, brass, lead, aluminum and incineration industries.